Your Cart is Empty

Get on track. 2022+ BRZ/GR86 and 2022+ WRX products in stock now!

Get on track. 2022+ BRZ/GR86 and 2022+ WRX products in stock now!

Get on track. 2022+ BRZ/GR86 and 2022+ WRX products in stock now!

February 19, 2020 2 min read

Previously on The Apex Files, we talked about the function of dampers as well as the definitions of shocks, struts, and coilovers. This time, we’re going to over the differences between monotube and twintube dampers. We’ll also discuss inverted dampers, piggyback canisters, and remote reservoirs.

If you don’t learn anything else from this post, just remember an important lesson: even the coolest looking dampers with all the bells and whistles can suck really badly.

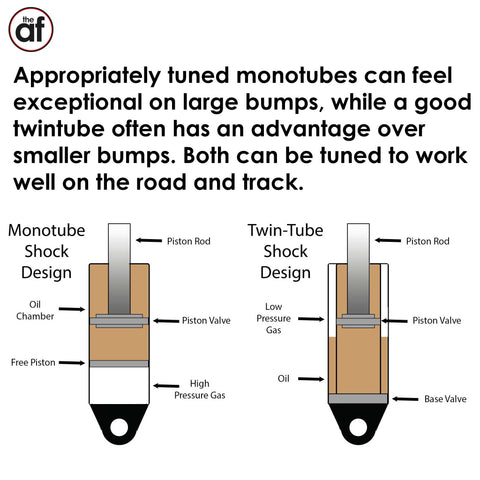

A monotube has a relatively simple design. There’s a shaft with a piston that pushes through a chamber of oil. All fluid valves are on this piston. Another piston keeps the oil from a separate gas chamber. This is all contained in a single tube.

A twintube has an inner and an outer tube. The inner tube has a piston with valves pushing through oil, but there is no separator for oil and gas. A base valve also contributes to damping and serves as the interface between the inner and outer tubes.

The larger pistons on monotubes allow for precise and consistent damping. Higher gas pressures, larger fluid capacity, and the separation of oil and gas allows them to handle heat better than twintubes. They are also easier to rebuild and revalve.

Twintubes use lower gas pressures and generally have less friction, resulting in a more comfortable ride. For a given shock length, a twintube will also have more travel. They are less expensive to manufacture in large quantities, but more difficult to service.

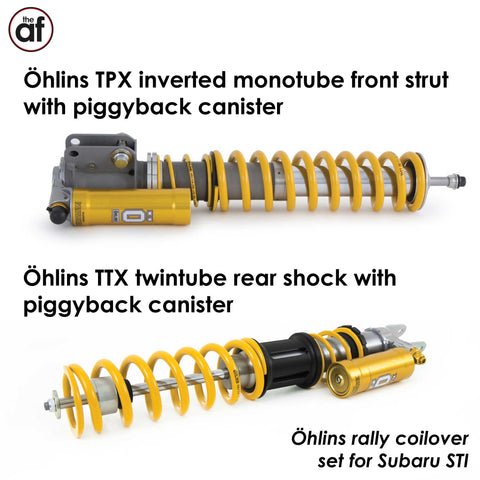

An inverted damper is a damper (usually a monotube strut) that is mounted upside down. The result is more strength for handling large side loads. This is great for rally cars and cars that see high lateral g-forces. They may require a little bit more maintenance than right-side-up dampers.

Inverted struts may look like they have massive shafts compared to regular shocks, but the shaft is actually inside the body and usually the same size as a conventional damper.

Piggyback canisters and remote reservoirs are frequently used on high end shocks. A piggyback canister is located on the shock while a remote reservoir can be located in the engine bay or inside the car.

The advantage is increased travel as well as more fluid capacity, which reduces the chance that performance will degrade due to heat. These components also generally include more advanced damper adjusters for improved damping control.

It’s still possible to have an inverted monotube coilover with remote reservoirs that sucks. The things you can’t see, like the quality of the piston, the shims, and the shaft, are very important. The bottom line is that a good twintube is better than a bad monotube, and vice versa.

You can also have a very good and very expensive shock, but a terrible valving profile. Or the adjusters may be set incorrectly. Next time, we’ll talk about the difference between compression and rebound damping.